M-D Building Products 28571 13-Inch Flap and Hood Mail Slot,Black. 4.3 out of 5 stars 20. 36 $36.37 $36.37. Get it as soon as Mon, Dec 21. Slotted flap is an improved version of the plain flap, generating more lift (a fact I don't challenge). However the principle is air passing between the wing and the flap.

- Fowler flaps often have a series of slots to add energy to the airflow as well - they're called slotted-Fowler flaps. In the first stages of a Fowler flap's extension, there's a large increase in lift, but little increase in drag, making the setting ideal for takeoff in a large jet.

- Flaps Both Sides Mail Slots. Oil Rubbed Bronze finish is a chemically darkened surface designed to simulate aged bronze with a matte lacquer applied. This finish is very dark and varies from a deep chocolate brown to a dark gray and usually has reddish undertones.

- Among the most commonly used flaps on modern aircraft are slotted flaps. Like other flaps, they increase the camber of the wing, but they also create a slot between the flap and the wing. The slot allows the high pressure from under the wing to flow through onto the upper surface.

Krueger flaps, or Krüger flaps, are lift enhancement devices that may be fitted to the leading edge of an aircraft wing. Unlike slats or droop flaps, the main wing upper surface and its nose is not changed. Instead, a portion of the lower wing is rotated out in front of the main wing leading edge. Current Boeing aircraft, and many others, use this design between the fuselage and closest engine, where the wing is thickest. Outboard of the engine, slat flaps are used on the leading edge. The Boeing 727 also used a mix of inboard Krueger flaps and outboard slats, although it had no engine between them. Most early jet airliners, such as the Boeing 707 and Boeing 747, used Krueger flaps only.

Operation[edit]

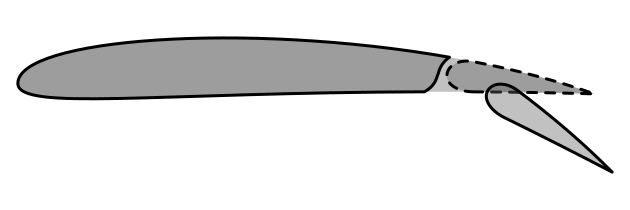

While the aerodynamic effect of Krueger flaps may be similar to that of slats or slots (in those cases where there is a gap or slot between the flap trailing edge and wing leading edge), they are deployed differently. Krueger flaps, hinged at their foremost position that once deployed actually become their trailing edges, hinge forwards from the under surface of the wing, increasing the wing camber and maximum coefficient of lift.[1] It produces a nose-up pitching moment. Conversely, slats extend forwards from the upper surface of the leading edge. Also, when deployed, Krueger flaps result in a much more pronounced blunt leading edge on the wing, helping to achieve better low-speed handling. This allows smaller-radius wing leading edges, better optimized for cruise. Leading edge Krueger flaps enhance wing's low speed lift production especially on swept wing aircraft. [2]

The Krueger flaps developed for the Boeing 747 were constructed from fiberglass honeycomb material and were designed to be intentionally distorted into an aerofoil section on deployment.[3]

History[edit]

Krüger flaps were invented by Werner Krüger in 1943 and evaluated in the wind tunnels in Göttingen, Germany.[4] One of the earliest civil applications was the Boeing 707 whereas swiss FFA claimed the first use of the flap in its FFA P-16 fighter which flew in 1955.[5] The flap was added to prevent wing stall with an extreme attitude take-off with the tail dragging on the runway, a scenario that had caused two de Havilland Comet accidents. A preliminary flight test had been made on the Boeing 367-80 using a fixed flap and a skid on the after-body.[6] After the Boeing test flight on the B-707 prototype on 15 July 1954, Krueger flaps were first used in production for the B-727 which made its maiden flight on 9 February 1963.[7]

Krueger flap operation

Slat operation

Boeing commenced a series of test flights on 17 March 2015 with a modified Boeing 757, incorporating new wing-leading-edge sections and an actively blown vertical tail.[8] The left wing has been modified to include a 6.7 m-span glove section supporting a variable-camber Krueger flap which will be deployed during landing and which protrudes just ahead of the leading edge. Although Krueger flaps have been tried before as insect-mitigation screens, previous designs caused additional drag. The newer design being tested is variable-camber and designed to retract as seamlessly as possible into the lower wing surface. Increasing the use of natural laminar flow (NLF) on an aircraft wing has the potential to reduce fuel burn by as much as 15%, but even small contaminants from insect remains will trip the flow from laminar to turbulent, destroying the performance benefit. The test flights have been supported by the European airline group TUI AG and conducted jointly with NASA as part of the agency’s Environmentally Responsible Aviation (ERA) program.

See also[edit]

References[edit]

Slot Flops

| Wikimedia Commons has media related to Krueger flaps. |

Notes[edit]

- ^Gary V. Bristow (2002). Ace the Technical Pilot Interview. McGraw-Hill Professional. ISBN0-07-139609-8. Retrieved 2009-02-16.

- ^Wyatt, David (21 August 2014). Aircraft Flight Instruments and Guidance Systems: Principles, Operations and ...books.google.com. ISBN9781317938316. Retrieved 16 July 2020.

- ^Taylor 1990, p. 114.

- ^Niels Klußmann; Arnim Malik (2012). Lexikon Der Luftfahrt. Springer. pp. 193–. ISBN978-3-642-22500-0.

- ^X-Planes of Europe II, Tony Buttler Hikoki Puplication 2015. Page 193. ISBN978-1-9021-0948-0

- ^'The Road to the 707' Cook, William H., TYC Publishing Company, Bellevue, 1991, ISBN0-9629605-0-0, p.249

- ^Hitchens, Frank (25 November 2015). The Encyclopedia of Aerodynamics. books.google.com. ISBN9781785383250. Retrieved 16 July 2020.

- ^'757 EcoDemo Focuses On Laminar And Active Flow'. Aviation Week. 23 March 2015. Retrieved 23 March 2015.

Bibliography[edit]

- Taylor, John W.R. The Lore of Flight, London: Universal Books Ltd., 1990. ISBN0-9509620-1-5.

| PRODUCT # | DESCRIPTION | LIST PRICE |

| A07-M0010-605 | 3-5/8' x 13' | 85.00 |

| A07-M0010-609 | 3-5/8' x 13' | 85.00 |

| A07-M0010-613-VB | 3-5/8' x 13' | 85.00 |

| A07-M0010-619 | 3-5/8' x 13' | 85.00 |

| A07-M0010-PVD | 3-5/8' x 13' | 105.00 |

Hole size required 2-3/4' x 11-5/8'

| PRODUCT # | DESCRIPTION | LIST PRICE |

| A07-M0050-605 | 3' x 10' | 56.00 |

| A07-M0050-609 | 3' x 10' | 56.00 |

| A07-M0050-613-VB | 3' x 10' | 56.00 |

| A07-M0050-619 | 3' x 10' | 56.00 |

| A07-M0050-PVD | 3' x 10' | 75.00 |

Hole size required 2-3/8' x 8-3/8'

Polished Brass

Polished Brass finish is solid brass that is polished and gloss lacquer coated to prevent tarnishing over time. Common finish codes for polished brass are 605 and US3. Also available un-lacquered that can be waxed or allowed to age naturally.

Polished Chrome

Trivalent Chrome is a new “green” chrome finish that eliminates the health and environmental concerns associated with hexavalent chrome. Trivalent chrome has the same tough, highly reflective, slightly blue cast of traditional hexavalent chrome. Chrome lead time is approximately 4-6 weeks. Common finish codes for chrome are 625 and US26.

BRASS Accents does custom matching to your finish sample on a quote basis only. We also do finish work on your brass hardware, again on a quote only basis.

Gloss Black

Powder Coat Finishes.BRASS Accents provides a wide assortment of powder coat finishes which are satin textured finishes designed to simulate iron hardware. Finish code GB.

Polished Nickel

Polished Nickel finish is nickel plated brass, polished to a high shine and clear gloss lacquer coated. This is a warm bright finish without the harsh look of chrome. Finish code 618 and US14.

Gloss Red

Powder Coat Finishes.BRASS Accents provides a wide assortment of powder coat finishes which are satin textured finishes designed to simulate iron hardware. Finish code RD.

Antique Nickel (Pewter)

Antique Nickel (Pewter) finish is nickel plating on brass that has been dulled and darkened to simulate pewter with a matte lacquer applied. This may be referred to as pewter or antique nickel interchangeably. Common finish codes for antique pewter are US15A and 620.

Gloss White

Powder Coat Finishes.BRASS Accents provides a wide assortment of powder coat finishes which are satin textured finishes designed to simulate iron hardware. Finish code WT.

Antique Copper

Antique Copper finish is copper plated brass chemically darkened to simulate aged copper with a matte lacquer applied. Antique Copper finish is typically a medium black with copper undertones, and can vary significantly from one product to another. To ensure that the finish is right for you, samples should be ordered in advance. Common finish code for antique copper is 657.

Oil Rubbed Bronze

Oil Rubbed Bronze finish is a chemically darkened surface designed to simulate aged bronze with a matte lacquer applied. This finish is very dark and varies from a deep chocolate brown to a dark gray and usually has reddish undertones. There are quite a variety of interpretations of this finish in the hardware industry and all oil rubbed bronze finishes do not match. To ensure that the finish is right for you, samples should be ordered in advance. Common finish codes for oil rubbed bronze are US10B and 613.

Satin Nickel

Satin Nickel finish is nickel plating on brass that has been satin finished with an abrasive and matte lacquer coated. Common finish codes for satin nickel are US15 and 619.

Aged Brass

Aged Brass much more realistically replicates the look of actual antique brass hardware. This finish is hand done in the USA by our skilled metal finishers with a gloss lacquer applied and offers the imperfections and soft patina look of actual antique hardware. Finish code 486.

Antique Brass

Antique Brass finish is solid brass which has been chemically darkened and highlighted with an abrasive to simulate aged brass. Antique Brass finish is typically a medium brown with golden undertones with a matte lacquer applied, and can vary significantly from one product to another. To ensure that the finish is right for you, samples should be ordered in advance. Common finish codes for antique brass are US5 and 609.

Highlighted Brass

Highlighted Brass is a special finish with gloss lacquer applied, designed to show off the exquisite detail of our hardware while allowing customer to maintain a polished brass finish. Finish code 610.

Satin Brass

Satin Brass finish is a brass that has been dulled and matte lacquer coated. Common finish codes for satin brass are US4 and 606.

Weathered Black

Powder Coat Finishes.BRASS Accents provides a wide assortment of powder coat finishes which are satin textured finishes designed to simulate iron hardware. Finish code Weathered Black 622.

Weathered Rust

Powder Coat Finishes.BRASS Accents provides a wide assortment of powder coat finishes which are satin textured finishes designed to simulate iron hardware. Finish code Rust 770.

Slats Flaps Difference

Distinctive craftsmanship.

Old-world tradition.

Slats Flaps And Ailerons

The finest example of classic styling, timeless beauty and enduring quality, the hallmarks of BRASS ACCENTS, one of the worlds leading crafters of cast-brass and hot-forged decorative brass hardware. Call for a price list and catalog today.